BASF has introduced a new wetting agent to help overcome dry patches that can occur in multi-effect distillation (MED) desalination plants.

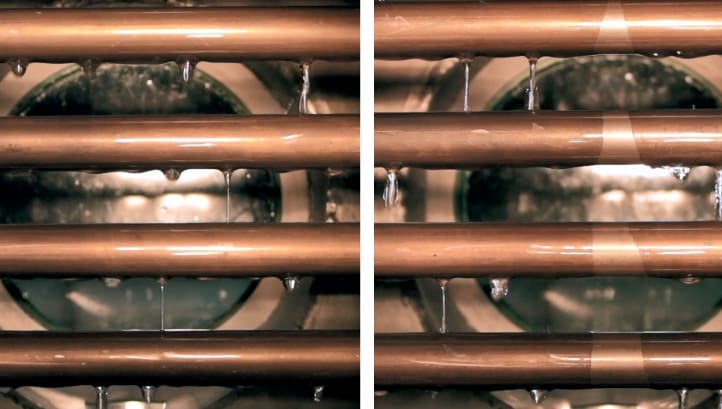

Particularly, the horizontal tube falling evaporators used in MED plants are prone to dry spots, creating uneven distribution of seawater and film breakdown, and threatening the smooth running of the plant.

Dry patches reduce the effective wet area, decrease the overall heat transfer co-efficient, and promote scaling.

Bascal HP 100 wetting agent addresses these concerns by reducing dynamic surface tension. The dosage affects seawater film flow characteristics, preventing film breakdown in the event of liquid maldistribution and declining flow rate.

Bascal HP 100 can help horizontal evaporators to fulfill zero liquid discharge requirements, and enables plant design to be optimized by defining a lower wetting rate.

Further, BASF is promoting a foam control agent, and an antiscalant, at the show.

The firm has developed Sokalan AF-X, a foam control agent that is readily biodegradable, fully water soluble, and effective at low dose rates. The new agent was developed to overcome some of the drawbacks of existing foam control agents, including lack of water solubility and poor biodegradability. In the case of MED and multi-stage flash distillation (MSF) desalination plants, the properties of the new agent can help to reduce the cost of cleaning and enable plants to operate for longer.

BASF also offers Sokalan RO 3500, a polymer based antiscalant that helps to keep reverse osmosis membranes free of inorganic scales and metals fouling. The company claims that Sokalan RO 3500 is environmentally friendly compared to more commonly used organophosphonate antiscalants, which are suspected to cause excessive algae growth.