Innovations in feed spacer technology can enhance the performance of reverse osmosis (RO) technologies, write Dr Carsten Schellenberg and Alan D Sharpe of Conwed Plastics and LAXNESS.

The world is running out of water. By 2025, nearly 1 billion people will lack access to fresh, drinkable water. Reverse osmosis water treatment will play a major role in alleviating water scarcity; however, this desalination technique is energy intensive. Any improvement of the membrane or element technology that can increase the energy efficiency of the reverse osmosis process will be important. In a co-research project, Conwed Plastics and LANXESS’ Liquid Purification Technologies business unit have proven that innovations in feed spacer technology lead toward enhanced RO element performance.

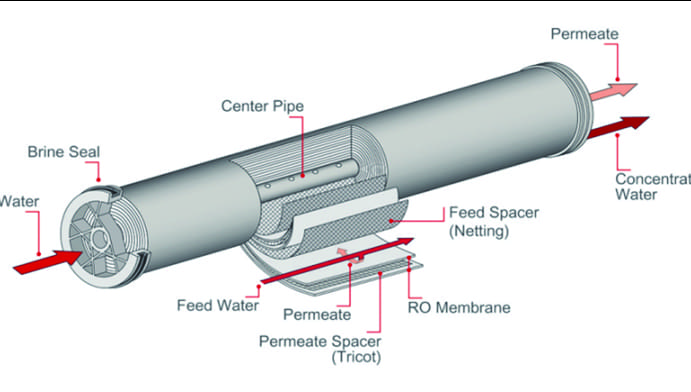

Reverse osmosis is a water purification technology to remove mainly monovalent ions (such as NaCl) that utilises a semi-permeable membrane. An applied pressure is used to overcome natural osmotic pressure. Such reverse osmosis membranes are being offered as spiral wound elements for a huge variety of desalination applications. Frequently known as scrim, mesh, net, or netting, feed spacers act as one of the layers of spiral wound RO elements, and provide vital separation between the membranes to achieve superior filter performance.

A spiral wound element refers to a membrane configuration that comprises “flat sheet membrane — permeate channel spacer — flat sheet membrane — feed channel spacer” combinations, rolled up around a permeate collection tube. As shown in Figure 1, the membrane element structure contains the feed spacer that separates the surfaces of adjacent membrane envelopes. The feed spacer, configured as a net, keeps the feed channel open, allowing feed water to flow inside the feed channels, along the membrane element.

Continue reading this article in the digital edition of Water. desalination + reuse.