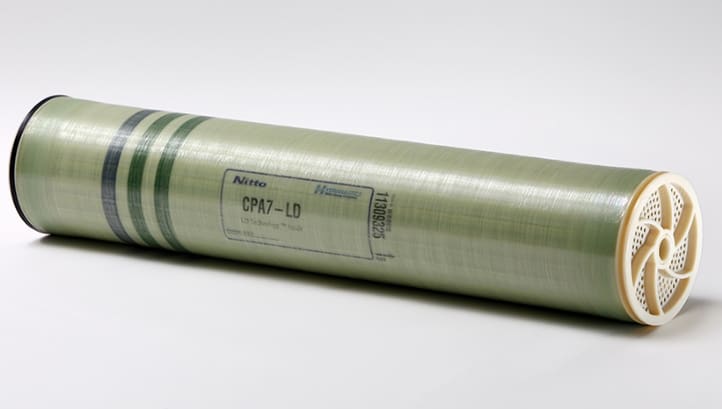

Hydranautics has brought out two new spiral wound reverse osmosis membranes for demanding industrial and municipal applications.

CPA7-LD, a sixth generation membrane, provides 99.8 per cent salt rejection, and 11,500 gallons a day permeate flow. The new membrane is designed to produce low permeate total dissolved solids (TDS) make-up water for power stations, and the semi-conductor and pharmaceutical industries; and it can treat high TDS brackish water sources.

ESPA2-LD MAX is a 440 square foot membrane with a 34mm-thick feed spacer, making it 10 per cent larger than existing 34mm feed spacer membranes. The increased surface helps to reduce cost either by reducing the number of membrane elements required, or by using the same number of elements as a traditional design and decreasing feed pressure, thereby saving on energy consumption. Alternatively, existing projects can increase capacity by 10 per cent by replacing 400 square foot membranes with the new 440 square foot elements.

Both of the new spiral wound membranes use enhanced chemical resistance, innovative spacer design, and anti-fouling technology; and both can be used for treating difficult waters which previously may have required significant pre-treatment.