The new hybrid membrane-thermal system is to be installed in April and commissioning is expected to be completed by Q4 2019.

Continental Gold won an environmental license to develop a gold mine at the village of Buritica, northwestern Colombia, in 2016. The firm was granted permission to turn an existing, small-scale mine into an integrated mining and milling operation. Once complete, the $390.3 million development project will have constructed a mine site with capacity to process up to 3,200 tonnes a day.

The miner wanted a solution for managing water supply and treatment at the site. The system would need to meet Columbia’s wastewater discharge regulations and overcome the logistical challenges of installation in the Andes: the mine site in Antioquia state is 2,000 metres above sea level at its highest point and two hours by car from Medellin city.

Aquatech configured a membrane-based treatment system to meet the site’s requirements. “The wastewater produced by the mining process is high in chlorides such as sodium chloride, as well as sulfates sodium, magnesium and calcium, heavy metals arsenic, cadmium and zinc, and other constituents of emerging concern,” explains Aquatech senior sales manager Ashwin Thakkar. “Conventionally, to do this type of wastewater treatment, you need high-density sludge handling clarifiers. They take up a lot of space and are not adaptable to flow rate changes. A membrane-based approach is light, flexible, and in terms of performance provides consistent, high-quality filtration configured in a container offering.”

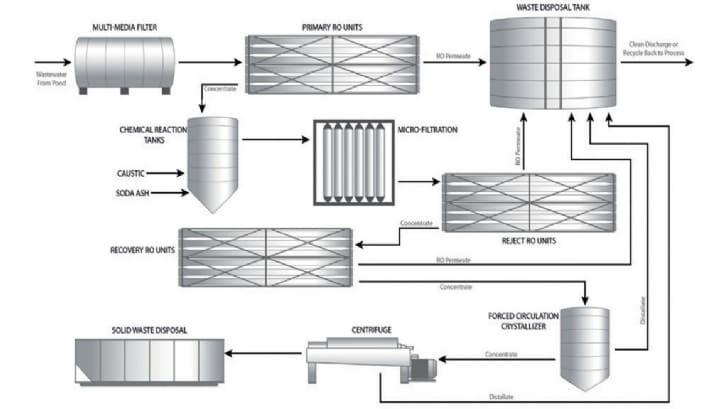

The system (see picture) first collects the mining process wastewater into a pond. Suspended solids are removed from the water by a multi-media filter in preparation for the first reverse osmosis (RO) step. After the RO, the permeate goes for reuse and the concentrate is treated for hardness before being put through a ceramic micro-filtration (MF) system. The micro-filtered concentrate then continues through two more RO stages, with permeate going for reuse. Finally, the concentrate goes to a crystalliser and is turned into solid waste for disposal in landfill.

“The design does not push the RO to its limits. Conventionally, MF and caustic lime dosing to take care of the heavy metals are done up-front – in this case the clarifiers will be large. We reduce that capacity down to 30 per cent. The MF is doing 30 per cent of the softening work compared to a conventional clarifier footprint. Overall we have reduced the capacity that goes to the crystalliser to 6.8 m3/h,” says Thankkar.

First of a kind

The system is entirely modular. Even the crystalliser is mounted onto a “super skid”, says Thakkar. Compared to a conventional set-up, the membrane-based approach aims to reduce footprint, cut energy consumption and minimise maintenance downtime. Once installed, the system will be the first of its kind operating in mining in South America.

At first, Continental Gold was planning on discharging the treated wastewater into the local water system. (It meets all the requirements of the site’s discharge permit under Resolution 631 of Columbia’s environmental laws.) However, the miner is now installing additional pipes to enable the water to be reused on the site. “We explained that with this system Buritica is a unique mine facility and should probably recycle. Continental Gold now sees how that could work,” adds Thakkar.

Aquatech specialises in a membrane-based approach to industrial wastewater treatment. The firm has 100 membrane-based zero liquid discharge (ZLD) systems operating worldwide, including about 40 which are hybrids. “Most people think of ZLD as a brute force thermal application. Hybrids can be more efficient because incorporating membranes reduces thermal footprint,” Thakkar says.

“Every mine site is different and every wastewater is potentially different. But, based on certain steps – whatever the dissolved solids or other constituents of concern – the system doesn’t have to be the same.

The concept is similar and the membrane approach replicable with differences in the chemical dosing,” says Thakkar. “All of our systems are a little bit different, even if they are in the same state. We tailor the configuration of the treatment to fit the site.”

Continental Gold is on schedule to pour first gold at the Buritica site in 2020. The 75,684 hectares site has two veins of high quality gold. The miner anticipates a second phase of development which will include additional water treatment capacity. A third stage is also a possibility. Aquatech’s modular approach will enable the water treatment capacity to scale up as required.