In part two of its pilot project digital diary, Dow Water & Process Solutions addresses the challenge of three very different petrochemical plant feed waters.

One of the project’s first big challenges was the combination of three very different feed water streams, all coming from the Repsol North cracker at the petrochemical plant in Tarragona. They comprise an intermediate stream, an oily stream, and a process stream, and this will be the first time that three such waters are combined and regenerated for industrial reuse.

We undertook a preliminary study of the different feed waters, to help guarantee the best design for the installation. The research included the study of biological parameters, conductivity, total suspended solids (TSS), and anion and cation relationship parameters.

The three streams have very different qualities, presenting a challenge for the system design. The intermediate stream, mainly coming from the blowdown of cooling towers and instrumental purges, presented the highest conductivity and the lowest organic carbon and toxic compound content. The process stream, where water is in contact with petroleum hydrocarbons, was the most complex in terms of recalcitrant organic compounds, organic nitrogen and iron. Finally, the oily stream, containing water mainly from the trench system at the olefins cracker and octene plants, was between the intermediate and process streams in terms of dissolved solids and organic carbon, but was enriched by volatile aromatic hydrocarbons, such as naphthalene and styrene.

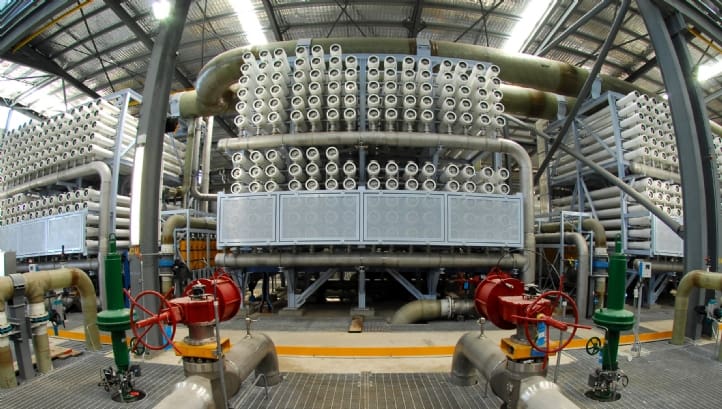

The goal was to design a system that could treat these three wastewater effluents and reuse the resulting water in Dow Chemical’s ethylene cracker at its facility in the Camp Tarragona petrochemical plant. The petrochemical industry generates around 1,750 hm3 of wastewater in Europe every year, making it the most water-intensive sector in the continent. The installation designed after the feed water analysis will help businesses in the sector to free up fresh water resources for municipal and other uses, and is a step on the road to a more sustainable petrochemical industry.

Alexander Lane is commercial director at Dow Water & Process Solutions

LIFE + REWATCH is a European Union-funded, three-year project that aims to treat and recycle petrochemical wastewater at Camp Tarragona, Spain.

For more information about Pilot Watch, contact the Editor.